Counter Flow Cooling Towers

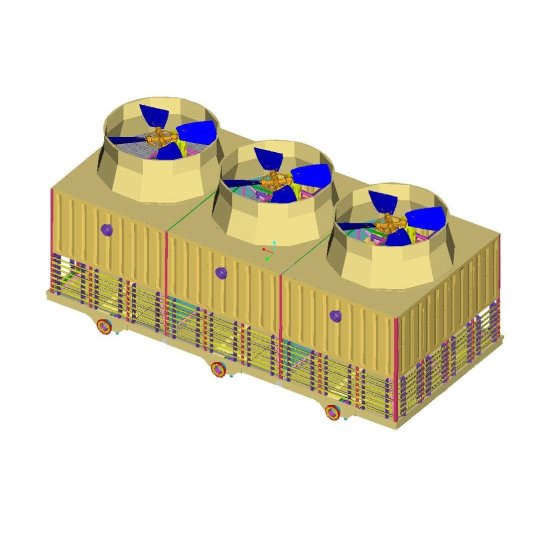

AT Series Induced Fan Counter-Flow Cooling Towers

The primary task of a cooling tower is to reject heat into the atmosphere. This heat rejection is accomplished through the natural process of evaporation that takes place when air and water is brought into direct contact in the cooling tower. The evaporation is most efficient when the maximum water surface area is exposed to the maximum flow of air in the longest possible period of time.

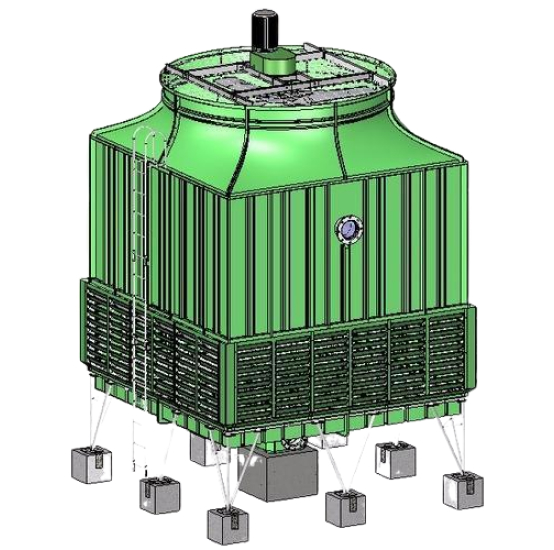

The air movement is vertically up through the fills in counter-flow to the downwards fall of the water. Counterflow towers in general use low pressure spray nozzles to divide the hot water equally over the infill surface in fine droplets. Counterflow designed cooling towers usually offer a smaller footprint than crossflow towers and allow maximum thermal performance out of each plan area. Counterflow towers also help minimize your pump head requirements.

This type of cooling tower is ideal with regards to space economy and cooling efficiency. The body of the tower is made of tough fiber glass reinforced plastic (FRP). It has sufficient structural strength to withstand high industrial vibrations and velocity. It is resistant to local impacts and even if damage is sustained local repairs can easily be done. Easy operating window is provided to inspect from where water distribution and fill can be observed clearly. Any repairing can be done through the window. Vibrations and noise are considerably reduced because fan is the only moving part of the cooling tower. In this type of towers the water produces a rain noise in the spraying area as well when it is falling from the infill media on to the water surface.

- Compact & Space Efficient Design

- Maximum Thermal Performance from given plane area

- Compensates for additional pressure drops

- Wide choice of models, cell sizes, and components

- Use of FRP composite material

- Corrosion resistant

- Weather Proof

ATCS - CFCT Series.