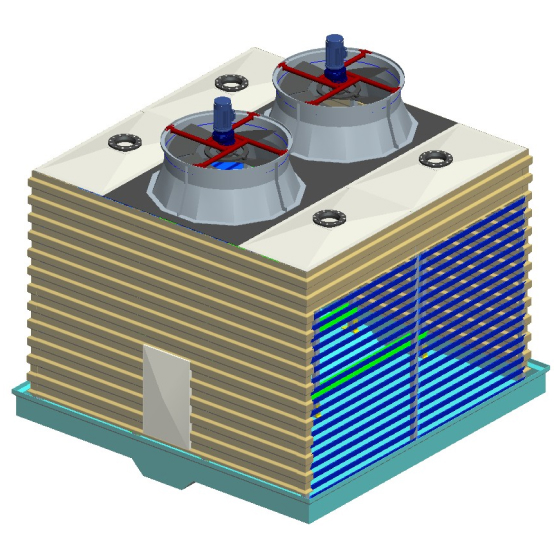

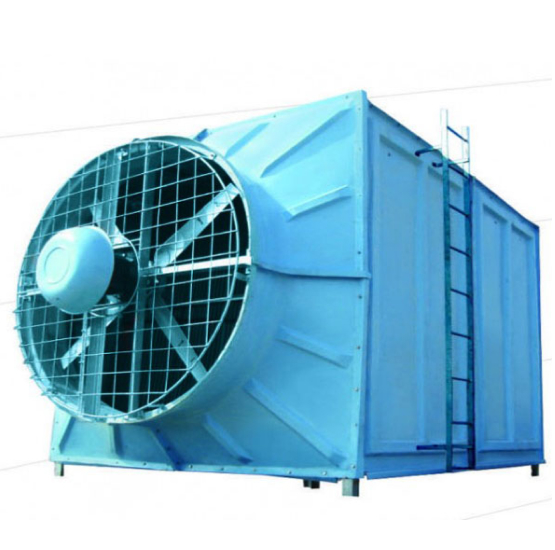

Cross-Flow Cooling Tower

AT Series Induced Fan Cross-Flow Cooling Towers

The primary task of a cooling tower is to reject heat into the atmosphere. This heat rejection is accomplished through the natural process of evaporation that takes place when air and water is brought into direct contact in the cooling tower. The evaporation is most efficient when the maximum water surface area is exposed to the maximum flow of air in the longest possible period of time.

Crossflow towers use a distinctly different type of water distribution system. The hot water is distributed to the splash fills by gravity through a perforated basin; sometimes supported by metering orifices or splash nozzles in the floor plate of the distribution tank. The water runs down over the infill surface made of plastic V-bars. The air meanwhile turbulates in a criss cross arrangement of splash bars infill structure in order to maximize the contact with the hot water. The pump head required is in general the tower height as static lift. The air movement is horizontally through the infill, across the downward fall of the water.

In crossflow towers the air comes into the infill over the total infill height. This results in low pumping head requirement which in turn yields in a lower operational cost. Drift losses are minimal due to the absence of water droplets but this results in a bulky and bigger design for the same output requirement when compared with counter-flow towers. A basic setback of this type of tower is that due to the fan configuration on top of the tower the air distribution is not equal over the whole inlet surface. In crossflow towers the noise of water is nearly absent.

- Minimized pump head requirements

- Lesser pumping and piping cost

- When noise limitations are of a significant factor

- Easily adaptable to variance in hot water flow

- Comparatively easy to maintain

- Use of FRP composite material

- Corrosion resistant

- Weather Proof

ATCS - SCRFCT Series.

ATCS - DCRFCT Series.